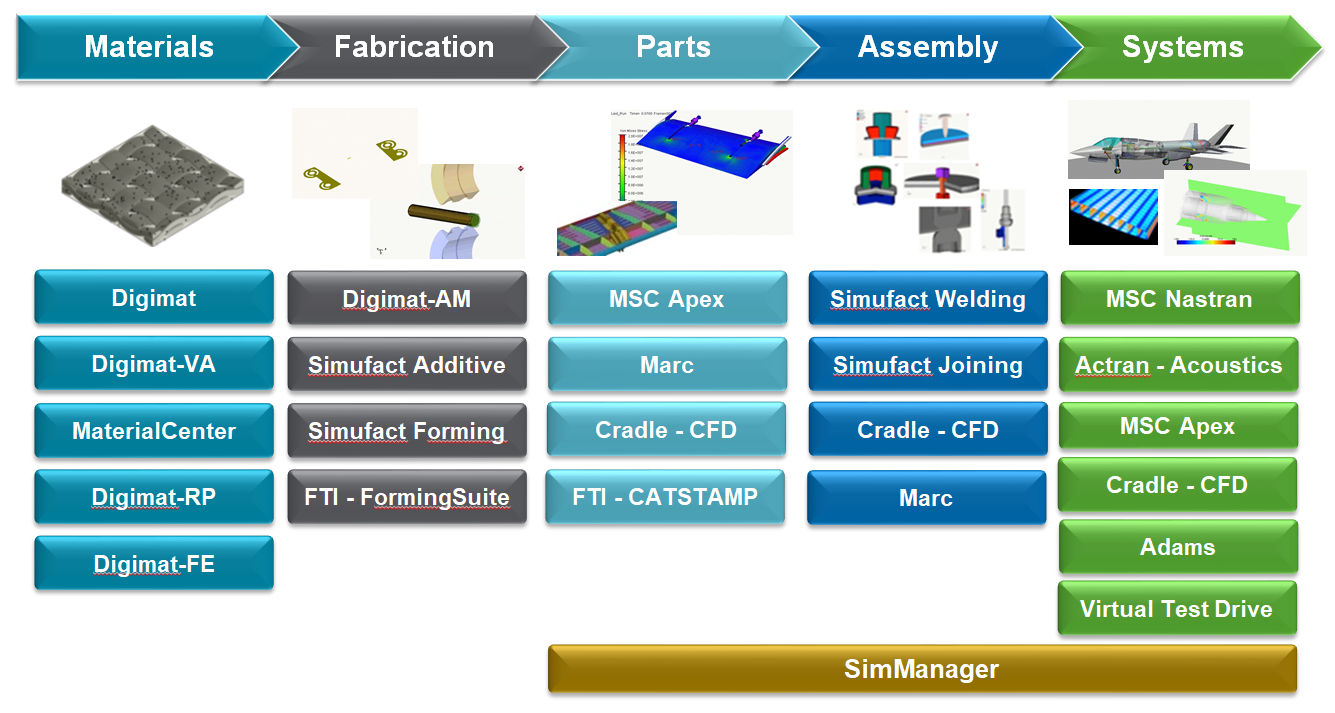

Use virtual prototypes to validate and optimize your design through simulation software Technology developed by MSC software. Customers in almost every part of manufacturing use MSC software to complement and replace the physical prototype “build and test” process that has traditionally been used in product design. MSC Software provides different products based on different engineering Industries like Civil Automobile, Aerospace Structural, Heavy Equipment Construction, Marine, Thermal Engineering Solar Energy, Rotating Equipment Transmission System, Automobile Production Engineering, Additive Manufacturing, Piping, etc.

Below are product based differences that make MSC different from other Multiphysics software like Ansys and Comsol.

Apex: MSC Apex is the world’s first computational parts based CAE system that will serve as the platform for a broad range of physics and applications that MSC Software will introduce over time. MSC apex includes User-friendly GUI, a platform for meshing and performing simulation analysis, structural analysis capability, and Optimization and Parameterization while other competitor software has Difficult and complex geometry with limited features no structural analysis to perform.

Nastran: A multidisciplinary structural analysis application used by engineers to perform static, dynamic, and thermal analysis across the linear and nonlinear domains, complemented with automated structural optimization and award winning embedded fatigue analysis technologies, all enabled by high-performance computing. Other competitor software for Nastran is less accurate and precise in structural solving with no possibility for automated structural optimization. Nastran can perform Multidisciplinary structural analysis like fatigue, vibration, NVH, Durability at one while other software cannot perform at ones and requires third-party software.

Patran: Patran is the world’s most widely used pre/post-processing software for Finite Element Analysis (FEA), providing a rich set of tools that streamline the creation of analysis ready models for linear, nonlinear, explicit dynamics, thermal, and other finite element solutions. Its preprocessing tool can perform complicated platforms to organized inputs to solve simulations and as its functions are user-defined one customize the code easily whereas in other multi-physics competitor software customization is complex and user-defined functions are not available.

Marc: Marc is a powerful, general-purpose, nonlinear finite element analysis solution that accurately simulates the product behavior under static, dynamic and multi-physics loading scenarios. Its versatility in modeling nonlinear material behaviors and transient environmental conditions makes it ideal to solve your complex design problems. It is optimized for non-linear analysis that incorporates all forms of nonlinearities including material, geometry, boundary condition with contact definition. Through Marc, one can predict failure and damage analysis with fast convergence whereas other software can perform nonlinear analysis with its limited specifications with no analysis on failure and damages.

Dytran: Dytran is an explicit finite element analysis (FEA) solution for simulating short-duration events like impact and crash, and to analyze the complex nonlinear behavior that structures undergo during these events. It is a stronger explicit solver and can perform explicit transient dynamic solutions for crash, impact, and fluid-structure interaction studies for improved product safety and can reduce warranty costs. The competitor software to dytran is less reliable with a time-consuming simulation process with less accuracy.

Sinda: Sinda is a thermal analyzer that is extensively used in a wide range of successful space programs including Astra, ERS 1-2, Gomos, Mars Express, Silex, Soho, and across multiple industries including Aerospace, Automotive, and Electronics. It is an advanced thermal analyzer tool with higher solver accuracy for applications like solar loads, solar power plants, space shuttles, satellites, etc. the competitor software for Sinda is poor in performing a thermal simulation and lacks in complex thermal simulation.

Adams: It is the world’s most famous and widely used Multibody Dynamics (MBD) software, which improves engineering efficiency and reduces product development costs by enabling early system-level design validation. Engineers can evaluate and manage the complex interactions between disciplines including motion, structures, actuation, and controls to better optimize product designs for performance, safety, and comfort. Adams software can perform multibody dynamic simulation along with load and force distribution to the system-level model. It provides an easy setup and user-friendly environment to create a deck to perform a complete automobile system whereas in other software model setup is time-consuming with no user-friendly interface.

Easy5: Easy5 can accurately simulate control systems, hydraulics (including thermal effects), pneumatics, gaseous flow, thermal, electrical, mechanical, refrigeration, environment control, lubrication or fuel systems, and sampled-data/discrete-time behavior whereas in other multiphysics software advanced control and system simulation are unable to perform in one module. To perform all these tasks different modules are required.

Simufact: A leading FEA based simulation solution for metal forming, welding and heat treatment. With the ability to simulate the entire manufacturing process chain, starting from blanking, shearing of wires or billets, to multi-stage forming, punching, trimming, and heat treatment followed by joining operations, welding and structural analysis, it helps to optimize the manufacturing processes, and reduce costs and time-to-market, while improving product quality. It can perfectly perform metal behaviour and can stimulate a complex welding process which includes multiple welding sequences and can predict distortions of the components with easy setup. The other multiphysics software has limited physics capability or may it not be available and can perform slowly with less accuracy.

Digimat: Digimat technology provides design tools that give the user 100% confidence in their composites products thanks to an accurate description of the local composite behavior. Accurate material modeling allows one to reduce the “factor of safety” – allowing composite materials to be used to 100% of their potential, maximizing their competitiveness against metal and leading to substantial weight reduction. Digimat tools integrate smoothly within the current FEA process, bridging the gap between the manufacturing process and structural analysis. It can investigate and predict the behaviour of a large mix of composite materials along with the design and manufacture of high-performance composite parts whereas a competitor software is complex in nature with limited material modeling.

scFLOW /scTetra: scFLOW is a CFD tool that uses unstructured mesh to accurately represent complicated geometry. With a Preprocessor that helps any level users generate high-quality polyhedral mesh elements and construct complicated models. With easy to perform DEM without a third-party tool, moving or overset meshing is easy to perform. While in other multiphysics software need an expert to handle and user-defined functions are required to perform moving mesh with solver capabilities.

scSTREAM/HeatDesigner: scSTREAM/heat designer is a general-purpose CFD tool that uses Cartesian or cylindrical structured mesh to enable easy mesh generation and high-speed simulations to be performed in a fraction of the time. It is the fastest and easiest tool to perform analysis on Electronics and Architecture simulation while other competitor software is Difficult to set up for open environments like architecture and complex environments like tsunami effect prediction etc.

PICLS: PICLS is a thermal simulation tool that helps designers easily perform thermal simulation of PCBs. Even if you are unfamiliar with thermal simulation, you will obtain a simulation result without stress through the tool’s easy and quick operation in 2D. It provides a customized tool to perform thermal simulation in PCBs/Electronic Components with faster analysis performance. The other multiphysics software is not easy to set up and to perform thermal simulation for PCBs/Electronic components.

Actran: Actran is the premier acoustics software to solve acoustics, Vibro-acoustics, and aero-acoustics problems. Used by automotive manufacturers and suppliers, aerospace and defense companies, and consumer product manufacturers, Actran helps engineers better understand and improve the acoustics performance of their designs. MSC’s actran can perform in complex acoustic problems with complicated environments and can be coupled with the FEA model. In other multiphysics software complex, acoustic problems and coupling are not possible. Coupling needs third party software.

SimManager:

SimManager is a Simulation Process and Data Management (SPDM) system that manages all aspects of CAE simulation with a focus on meeting the sophisticated data management and processing needs specific to the simulation community. As it is organized and customized one can easily visualize your data and compare with the existing one. The other competitor software needs a third-party tool to perform this feature.