Over the last 20 years or so, one of the ‘holy grails’ of computer-aided engineering (CAE) has been ‘multiphysics’ simulations, i.e. co-simulation between different physics simulation types (Ref. 1). Multiphysics, even though an ill-defined term, kind of feels intuitively right to us engineers from the perspective of real-world engineering simulation. Fluids don’t usually exist in isolation from structural effects acoustics, or dynamics in the real world we inhabit, yet for many years past, engineers have simulated these subdomains of physics as isolated point simulation solutions in CAE. I have to add a rider here that my Physics teacher at High School, Mr. Copeland, would have taken me to task for using the word ‘multiphysics’ at all because strictly it is wrong. There is actually only one discipline of physics, as there is for chemistry and biology. Within physics, there are subdisciplines like Newtonian Laws of Motion (and fluids), Maxwell’s Laws of

Electromagnetics, Structural Stress-Strain laws, etc. This ‘multiphysics’ word that was coined in the 1990s is actually a consequence of a failure of the CAE industry to solve the fundamental underlying physics equations in a combined way in my opinion. Partly, this is due to practical problems that we find because of different mathematical techniques. For instance, Finite Volume Methods (best for fluids), Finite Element Methods (best for structures and acoustics) mean that for more efficient solver convergence in real-world engineering problems, one or the other is chosen as the best methodology. And partly, software vendors have struggled to grapple with the multiphysics challenge to deliver usable engineering simulation tools because the mathematical approaches don’t tend to gel well together when combined.

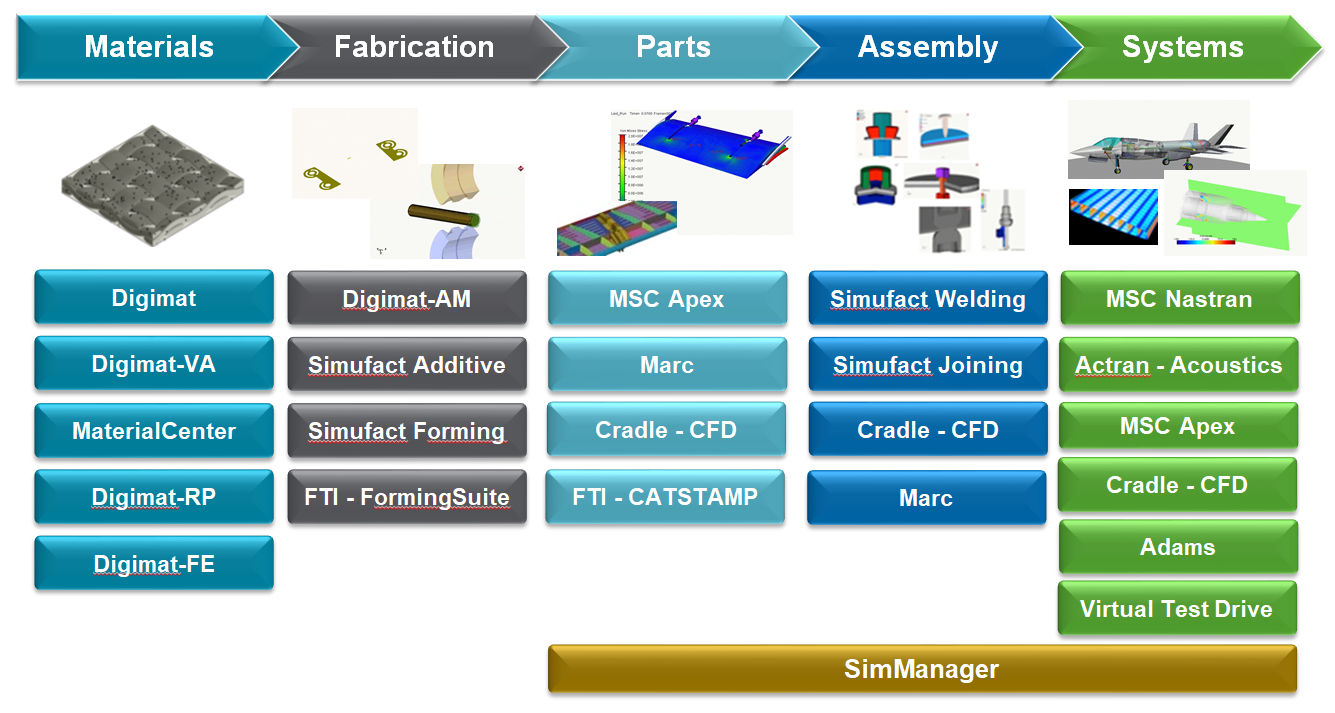

What was very striking about MSC Software when I joined earlier this year, apart from its 50+ year history stretching back to the early NASA moon landing project, and the desire for accuracy in software solutions, is a largely understated history of endeavoring to provide world-class CAE simulation solutions to its customers as well as engineers everywhere. Everything from acoustics to multi-body dynamics (MBD), to CFD, to structural analysis, and explicit crash dynamics can be connected together in MSC. I have gathered together a multiplicity of multiphysics co-simulation applications that can be done with MSC software tools today, both in two-product couplings, as well as in toolchains of product simulations that were mere pipe dreams a few years ago.

Multi-Body Dynamics Led Co-Simulation

When one digs down one soon discovers that the market-leading Adams MBD product is being used extensively for industrial-grade co-simulations around the world today as a matter of course, and is open to connections with all sorts of commercial and open-source software (see Figure 2). Some notable recent innovations are connections to the market-leading Discrete Element Modeling software, EDEM, from DEM Solutions, as illustrated by Figure 3, VIRES Virtual Test Drive (VTD) for ADAS and autonomous vehicle drive simulation (VIRES has been part of MSC/Hexagon since 2017), and of course MATLAB & SIMULINK for 0D/1D systems and controls modeling (from Math Works). Adams coupled with Marc can solve wiper blade movements, hydraulic actuators, rubber door seals, and full vehicle bush modeling. I will go into more detail below about the exciting new co-simulation multiphysics capabilities that the CFD software acquisition of Software Cradle by MSC Software in 2016 is now beginning to open up for CFD and CAE engineers alike. A very complex and challenging dynamic co-simulation is shown in Figure 4 where a non-linear bending and twisting metallic flap in a cross-flow was simulated in a scFLOW – Marc – MSC Nastran toolchain.

Acoustics Led Co-Simulation

Actran is recognized to be the market leader in acoustics simulation with a twenty-year history behind it and a blue-chip user base worldwide. It has many multiphysics acoustic applications like the classic one of coupling with CFD for aeroacoustic analysis. Actran provides today a complete end-to-end solution from mechanical load prediction to noise and vibration assessment. In a recent Webinar (Ref. 2) my colleagues Romain Baudson and Yijun Fan looked at acoustic predictions for electric vehicles with Actran led toolchains. Figure 5 shows the two toolchains they employed in their simulation analyses. Multibody simulation with Adams provides the structural loads when the conventional powertrain is operating, then MSC Nastran was used for vibration analysis. Finally, noise radiation is then computed with Actran with high accuracy in a fully automated process. By comparison, for Electric Vehicles, electromagnetic simulation results from various third-party software (for example, JMAG, MagNet, Maxwell…) can be integrated with MSC’s FEA tools for electric motor noise prediction. In so doing Actran provides accurate noise predictions for both the electric motor and the gear reducer. Finally, a relatively recent

acoustics and fluids co-simulation is illustrated in Figure 6 between Actran and scFLOW from Software Cradle where an automotive exhaust and muffler system was modeled in CFD and coupled with Actran for acoustic noise prediction.

CFD Led Co-Simulation

Computational Fluid Dynamics (CFD) has long been a passion of mine and it is genuinely quite exciting to see what is happening in Japan with Software Cradle’s co-simulation CFD efforts. They have devised a remarkably robust and open software platform for co-simulation (see Figure 7). Software Cradle’s CFD products – scFLOW (that employs polyhedral meshes), scSTREAM (with Cartesian meshes), and SC/Tetra (with tetrahedral meshes) have a long history of use by large OEMs and leading Japanese companies and come with a strong technical

pedigree. They are technology leading in free surface and overset meshing techniques with fast, accurate, and robust approaches. Physical quantities can be passed between the third party and MSC’s CAE software and Cradle’s CFD tools using its FMI (Functional Mockup Interface). The FMI supports general physical quantity settings, user-defined functions, and script languages. With Adams in particular, this co-simulation approach can do large particulate flows on free surfaces (Figure 8), vane pumps, washing machine drum vibration, and MBD fuel tank sloshing (Figure 9) for instance. A really exciting MBD application is that of a vehicle driving through a large puddle with suspension effects taken into account by Adams or the same vehicle’s dynamics in a crosswind (Figure 10). Co-simulation with Marc means that Cradle CFD couplings can do aircraft fuel tank baffles, liquid quenching, flexible plates/membranes/valve seals (Figure 11), and Sirocco fans. When coupled to MSC Nastran, scFLOW can do FSI of ship’s propeller with cavitation effects included for example (see Figure 12).

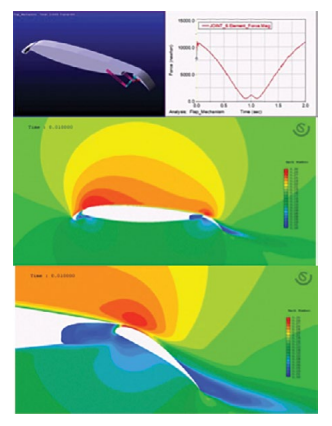

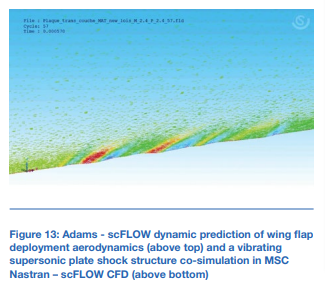

It’s the really cool co-simulation CFD applications that catch your eye the most, however. Software Cradle have coupled Adams with scFLOW to look at dynamic aircraft wing and flap deployment aerodynamic

predictions (see Figure 13). Another exciting new aerodynamic co-simulation application between scFLOW and MSC Nastran / Marc is the non-linear panel flutter of a supersonic plate (Ref 3), involving a highly unusual coupled undulating vibration of the flat plate’s surface at high speeds resulting in moving shocks on the surface (see Figure 13). It was accomplished by my colleague Fausto Gill di Vincenzo in Italy who employed our seamless MSC Nastran – scFLOW CFD coupling technology for an efficient and fast solution. The CFD domain deformation prediction was done with sliding mesh capabilities and then the FEA was performed by MSC Nastran and Marc. The CFD elements used could be tets, texas, or polyhedral elements.

Finally, another area of interest of mine is thermomechanical stress predictions for electronic components on chips and PCBs (Printed Circuit Boards). This application too is quite difficult to do as a co-simulation by most commercial vendors. In Figure 14 an electronic chip resistor has been simulated that undergoes repeated heat generation by its own on-off actions (Ref. 4). This will eventually cause the breakage of its solder joints over the lifetime of the component and ultimately product failure. Being able to predict it in advance and to locate high-stress areas is very important. Temperature distribution predictions from scSTREAM were mapped onto the mesh of the structural analysis solver (eg MSC Nastran or ANSYS Mechanical). The stress on the solder connection was then predicted. This is a very powerful way of predicting failure mechanisms and their likely locations in the consumer electronics industry and is relatively easy to do in scSTREAM as a co-simulation.

grade engineering application (either loose- or closely coupled CAE). So, ‘multiphysics’ is still one of the ‘Holy Grails’ of CAE solution even after 40 to 50 years of point simulations in all the physics sub-disciplines. MSC Software has grappled with this co-simulation conundrum and come up with many usable solutions and toolchains for real-world engineering applications. I would encourage you to explore what we offer and use MSC One credits to try them out. Ask your local MSC account manager or support engineer if you want to know more. We offer both the technologies and the professional services that can help you solve your industry CAE co-simulation challenges.

References

1. “Back to the Future; Trends in Commercial CFD” by J. Parry & K. Hanna, NAFEMS World Congress, Boston, USA, 2011: http://s3.mentor.com/public_ documents/whitepaper/resources/ mentorpaper_90428.pdf

2. “Noise Prediction for Electric Powertrain” Webinar, by R. Baudson and Y. Fan, August 2018: http://www. mscsoftware.com/events_assets/Webcasts/2018_ Webinars/noise-prediction-for-electric-vehiclepowertrain.html

3. “An Efficient Fluid Structural Workflow using the Seamless Coupling Technology” Webinar, August 2018: http://www.mscsoftware.com/events_assets/ Webcasts/2018_Webinars/an-efficient-fluid-structural workflow-using-the-seamless-coupling-technology within-MSC-Nastran-marc-and-sc-tetra.html

4. “Predicting Durability of Junctions for Mounted Parts” Cradle CFD Case Study: https://www.cradle-cfd.com/ images/applications/electronics/11ST_ MountedPartsDurability_email

Summary

Classical ‘multiphysics’ challenges for CAE include fluids and structures (FSI, VIV), structures and acoustics, structures and dynamics, and fluids and dynamics. Multiphysics simulation may sound easy in principle yet many commercial CAE vendors have had point physics solutions for decades now but have failed to implement usable coupled solutions for industrial

FOR MORE INFORMATION